IGBT Radiator

IGBT Radiator

Material Description

Copper

Aluminum Alloy

Copper-Aluminum Composite

Equipment

2500T Cold Forging Machine

Through-type Cleaning Machine

Drilling and Tapping Machine

3000t Cold Forging Machine

Abrasive Flow Polishing Machine

Production Line

Copper Plate Cold Forging Center

The company uses domestic famous cold forging equipment and is equipped with a high-precision robot operating system, which can realize automatic mold replacement; automatic product loading and unloading, automatic detection, and automatic transportation.

Copper Plate Processing Center

The company selects high-precision drilling and tapping machines, equipped with vacuum generators, automatic pressure retention systems, automatic oil filtering and removal, and oil mist collection systems.

Electroplating Center

The company is only 2 minutes away from the electroplating industrial park. It has a large electroplating laboratory and has obtained SAIC system certification, which can solve electroplating technology, quality, and inspection issues in a one-stop manner. The company has 20 acres of vacant land inside the industrial park, and it is expected to build an electroplating company in 2024, which can accommodate three electroplating production lines.

Packaging and Logistics Center

The company's packaging uses industry-specific packaging containers to vacuum-dehumidify the products and use knife cards for individual placement to ensure stable and safe product transportation.

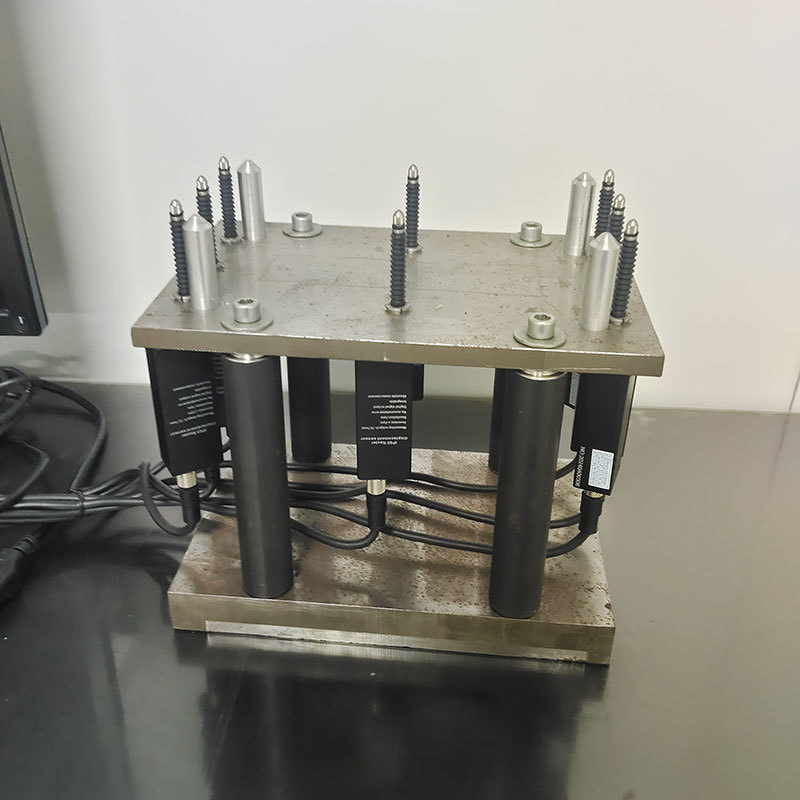

Testing Equipment

Arc detector

Salt spray testing machine

2.5D detectors

Vickers hardness tester

Typical Products

Round Needle-type Copper Radiator

Round Needle-type Copper Radiator

Round Needle-type Copper Radiator